CHOOSE

A DIFFERENT TERRITORY

From a family business to a global company driving innovation in sustainability, EMR has come a long way. Take a trip back in time to learn more.

EMR launched its long-term sustainability strategy (Our Decade of Action), in 2020, preparing our colleagues and customers for a greener, more circular economy.

Other recent work, such as the development of sector-specific apprenticeship training in 2018 and outreach in schools and communities, ensures EMR is taking positive action to improve the recycling industry worldwide.

In 2010, EMR invested in its stateside operations with the purchase of International Shipbreaking, enabling the company to recycle metals from the biggest decommissioned aircraft carriers in the US Navy. In the UK, the development of our Oldbury advanced separation facility helped the company increase its investment in research and get the business closer to its zero-landfill target.

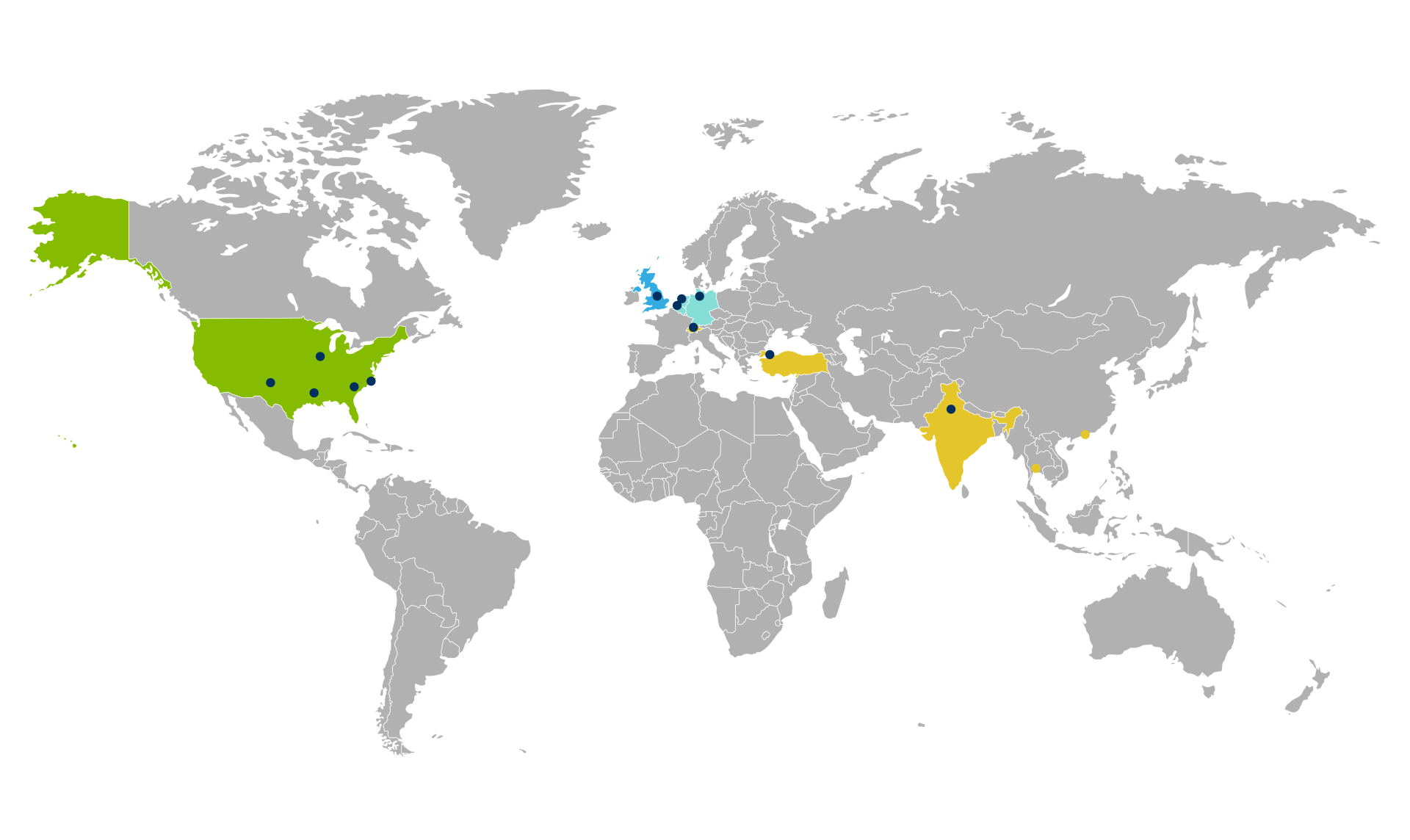

The 2000s saw EMR become the world-leading international metal recycler it is today. This began with acquisition of Newco’s European scrap terminals in the Netherlands and Germany.

In 2006, EMR acquired Camden and Southern, two predominantly ferrous recycling firms in the USA. This was soon followed by the Northern group of scrap metal businesses, allowing the company to substantially increase the volumes of recycled material we could trade within the USA.

In 2007, the UK’s second largest non-ferrous recycling firm, Mountstar, joined the group.

For much of its history EMR has been predominantly a ferrous focused business. This all changed in 2001 when the business acquired Mayer Parry, a ferrous competitor, which also had a substantial non-ferrous metals and advanced media operation – allowing EMR to expand its expertise. This ensured more of the scrap that was sold to the business could be put back into the circular economy. Since then, EMR has further added to its skillset with the arrival of plastics recycler MBA Polymers in 2010.

In the late 1980s and early 1990s, the company acquired two of its biggest competitors. In 1987, the Sheppard Group took over George Cohen’s 600 Group which included Cox & Danks Ltd, a salvage firm that had worked with the Titanic’s owner White Star Line, as well as the British Navy in World War Two. Then, in 1994, the company bought out another competitor — Coopers Metals — retaining the Sheppard family ownership but gaining a new name: European Metal Recycling, reflecting the ambition and growth of the business.

The start of the company’s growth began in 1978. That year the company gained its second site, a competitor’s yard in St Helen’s. Sheppards Waste Recovery became The Sheppard Group. By the early 1980s the company also leased an export facility in the Port of Liverpool, making it the first UK scrap metal business to enter the lucrative deep sea export market. From these three sites EMR has grown to operate around 160 today.

The 1960s and 1970s saw the company show the first glimpses of the ambition which would come to define its future. In 1968, the company made a significant investment in a new shear that substantially increased the volumes of scrap it could process. In 1976, the company again invested in state-of-the-art technology with the arrival of an innovative baling press that remains in operation in 2021.

At the origin of our business is the story of one woman’s dream of a better life for her family. In the 1940s, Winifred Sheppard left wartime London for the relative safety of Rochdale after a bomb destroyed the factory where she worked and her job was relocated to Greater Manchester. With her husband Herbert and children Bob, Stanley, Bert, George and Queenie, Winifred started the business at The Shed, in central Rochdale, moving premises over the next few years until they found a permanent site at Beal Works Mill which is still an EMR site today.

An amazing story was about to begin.